SEPRO Sr S5-35 S3 Trans robot available. Manufactured in 2017. Ideal for various applications. Professional and reliable choice for enhancing your automation needs.

Robot weight: 643Kg

Nominal load: 15kg

Outer dimensions, Y carriage and Z arm retracted: 3910 x 1880 x 1920 mm

Pneumatic operating pressure: :6 bar 10%

Maximum admissible pneumatic pressure: 7 bar

Nominal compressed air consumption: 180 I/min

Maxinstant compressed air consumption: 620I/min

Horizontal Movement of Carraige On Beam X:

Stroke: 98.42″

Motorization: Servo-controled brushless

Instantaneous linear speed: 3,50 m/s

Stop control: PTP linear numerical

Display resolution: 0.1 mm

Positioning precision DLX: 0.5 mm

Placing repeatability rx: 0 . 1 mm

Spacer between robot and platen: fixed under beam

Horizontal Demoulding Movement Y:

Stroke: 35.43″

Motorization: Servo-controlled brushless

Instantaneous linear speed:

Stop control: PTP linear numerical

Display resolution: 0.1 mm

Positioning precision DLy: 0.5 mm

Placing repeatability ry: 0 . 1 mm

Vertical Movement Z

Stroke: 70.86″

Motorization: Servo-controlled brushless

Instantaneous linear speed: 4,00 m/s

Stop control: PTP linear numerical

Display resolution: 0 . 1 mm

Positioning precision DLz: # 0.5 mm

Placing repeatability rz: 0 . 1 mm

Environment

Storage temperature / transport: -25°Cto + 55°C

Operating temperature: + 5ºCto + 40°C

Relative humidity: 30 to 95% without condensation

Maximum altitude: 2000 m

Radio frequency in common mode: 10kV

Electrostatic discharges: 8kV

Rapid transients on power supply: 4kV

Rapid transients on inputs/outputs by coupling: 2kV

Symmetrical high-energy puises: 1kV

Asymmetrical high-energy pulses: 2kV

Power transients at 1 Hz: 10 ms

Slow voltage variations of 1 volt per second: -15 % to + 1 0 %

Acoustic pressure level (weighted continuous decibel A): 70 dBA

Cabinet IPK protection: IP22, IK07

Pendant IPK protection: 1P32; 1K06

Touch screen Life time: 1,000, 000 hits (finger); 100,000 hits (character input

with 2h pencil hardness)

Touch screen chemical resistance: Toluene, Athetone, Gasoline, Machine Oil, Ammonia,

Glass Cleaner.

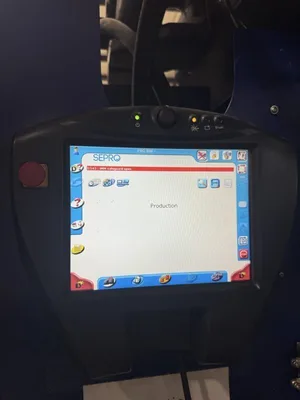

Electronic Control System Model: Visual2

Weight of control cabinet: 36kg

Outer dimensions: 460×360 x 636 m

Operating power supply voltage: 3x400V à 3x480V 1 0 % three-phase w/out neutral

Earthing System: TN or TT network

Operating frequency : 50/60 Hz

Nominal power : 1,5 kVA

Maximum power consumption : depends on robot cycle

Display : 10.4″ touch screen

Internal programs memory storage : 4Go on micro SD card

System memory storage : 512MB DDR & 512MB FLASH

Processor (1 to 2 CPU cards depending on the configuration) : iMX537 / Cortex A8 / 800 MHz

Input / Output interface on the robot : 2 x 16 inputs / 16 outputs modules

(digital input, 24 VDC 10mA/ digital static output, 6 to 35 VDC 500mA)

Input / Output interface on IMM Interface card : 7 inputs / 8 outputs

(digital input, 24VDC 10mA / digital output, 6 to 30VDC 500mA

USB Master interface for USB Key : USB Standard V2.0

USB Slave interface for PC link : USB S t a n d a r d V2.0

IMM link interface (real-time and digital) : Connection to EUROMAP 12 standard and AN146

PC link interface : Ethernet 10/100Mb/s

Control

Visual 2

We use cookies to improve your experience. Privacy Policy.